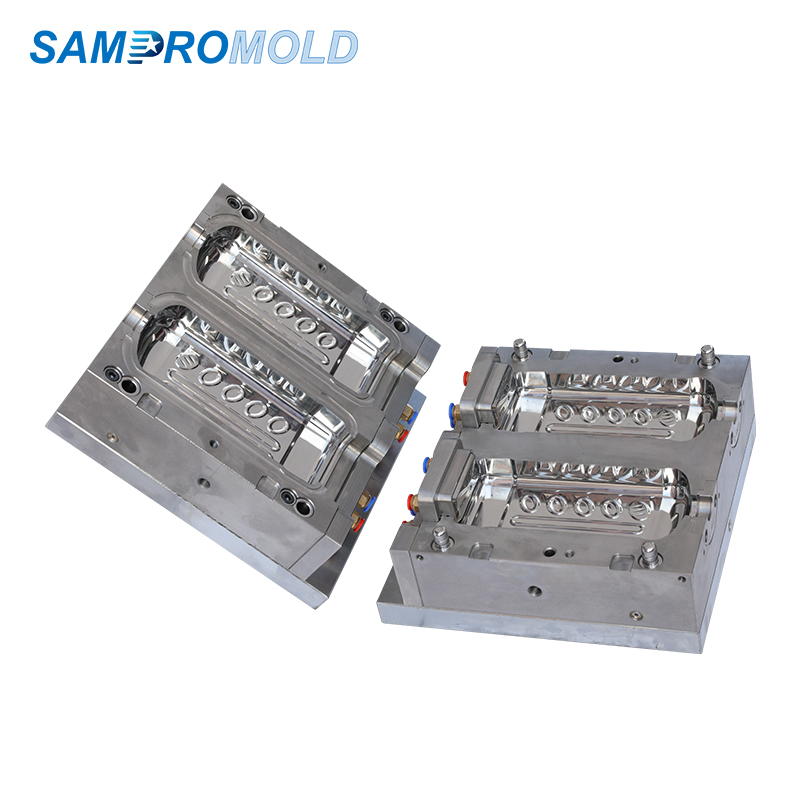

One of the latest innovations from Zhongshan Sampromold Co., Ltd. is the hot runner injection mould, a technology that has revolutionized the manufacturing process for plastic products. This advanced moulding technique offers numerous benefits, including improved efficiency, reduced production costs, and enhanced product quality.

The hot runner injection mould is designed to heat the plastic material in the runner system, ensuring that it remains in a molten state throughout the entire molding process. This results in smoother, more consistent product flow, and minimizes the risk of defects or imperfections. In addition, the use of hot runner injection moulds can lead to a significant reduction in material wastage, as there is no need to regrind or discard excess plastic.

With the ability to produce complex and intricate designs with precision and accuracy, hot runner injection moulds are particularly well-suited for the production of high-quality packaging solutions. From bottles and containers to caps and closures, this innovative technology offers endless possibilities for businesses looking to enhance their product offerings.

In addition to its technical capabilities, the hot runner injection mould also offers improved cycle times, resulting in higher productivity and faster turnaround times for orders. This is a significant advantage for businesses in the fast-paced packaging industry, where speed and efficiency are critical to meeting market demands.

For businesses in the daily chemical, lubricating oil, medicine, chemical, and food industries, the adoption of hot runner injection mould technology can provide a competitive edge in the market. With the ability to produce products that meet the highest standards of quality and consistency, companies can build greater trust and loyalty with their customers, and gain a reputation for excellence in their respective industries.

Zhongshan Sampromold Co., Ltd. understands the importance of staying at the forefront of technological advancements, and is proud to offer hot runner injection moulds as part of its comprehensive range of moulding solutions. With a strong focus on innovation and customer satisfaction, the company is dedicated to helping businesses achieve their production goals and exceed their customers' expectations.

As a trusted partner, Zhongshan Sampromold Co., Ltd. works closely with its clients to understand their unique needs and requirements, and provides tailored solutions to meet their specific objectives. Whether it's designing a custom mould or optimizing an existing process, the company's team of experienced professionals is committed to delivering top-quality results, every time.

With the introduction of its hot runner injection mould technology, Zhongshan Sampromold Co., Ltd. is poised to further solidify its position as a leading provider of moulding solutions for the packaging industry. By offering advanced capabilities that deliver superior performance and reliability, the company continues to set new standards for excellence and innovation in the field.

In conclusion, the hot runner injection mould from Zhongshan Sampromold Co., Ltd. represents an exciting advancement in the field of plastic moulding technology. With its ability to enhance efficiency, reduce costs, and improve product quality, this innovative technology is poised to drive significant benefits for businesses in the packaging industry. As the company remains committed to delivering exceptional results and exceeding customer expectations, it is well-positioned to continue shaping the future of the moulding industry with its groundbreaking solutions.