Injection moulding is a manufacturing process used to produce parts and products with consistency, high precision, and low cost. Injection moulding tooling is an essential component of the injection moulding process, as it determines the quality, reliability, and efficiency of the final product. In this blog post, we will explore the benefits of injection moulding tooling and how it can help businesses to reduce costs, increase productivity, and improve their bottom line.

What is Injection Moulding Tooling?

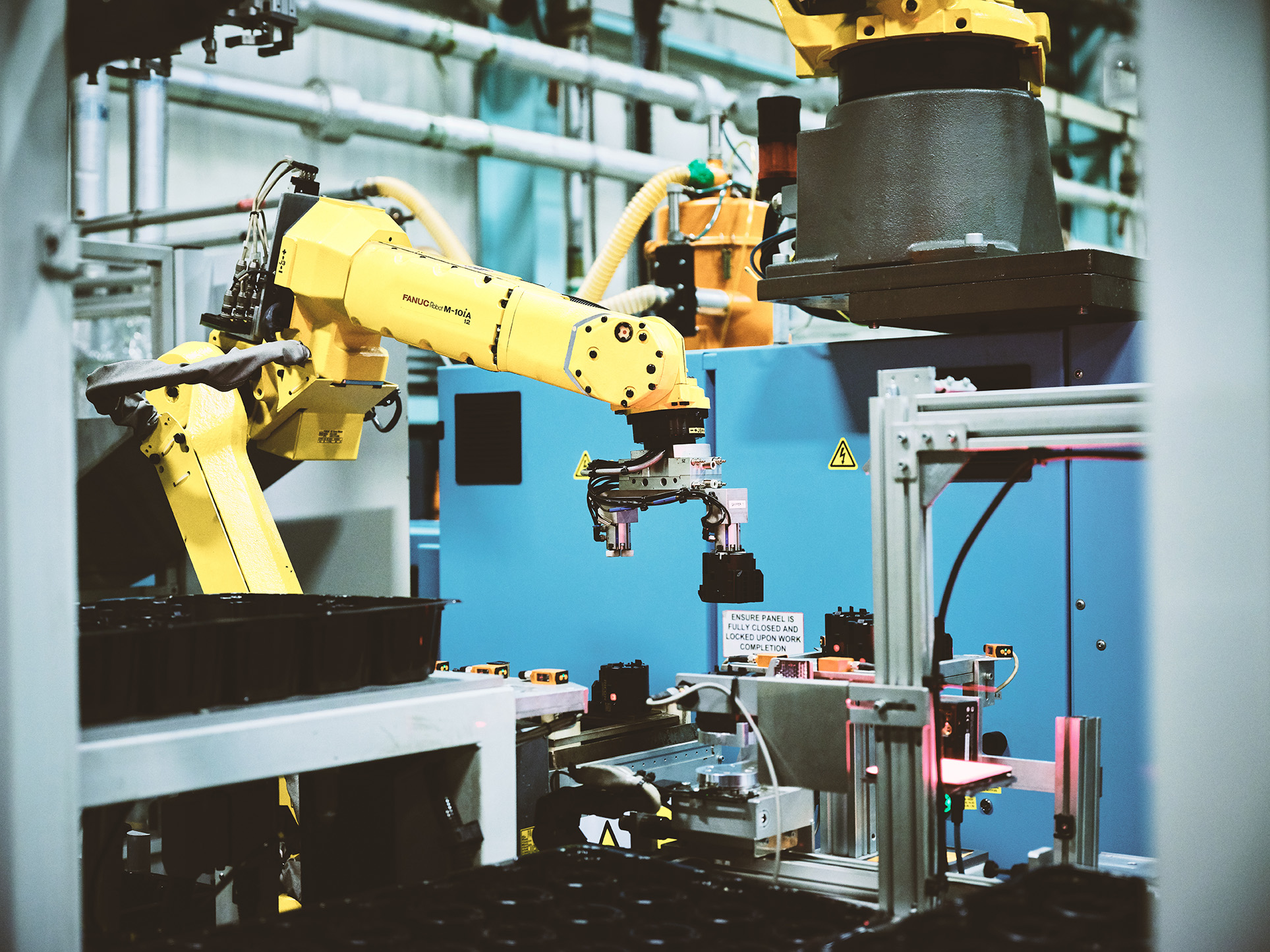

Injection moulding tooling refers to the collection of tools and equipment used to produce plastic parts through the injection moulding process. The tooling includes the mould itself, as well as a range of other components such as the runner system, gating system, ejector pins, and cooling system. The design and manufacture of the tooling are critical to the success of the injection moulding process, as it affects the quality, consistency, and efficiency of the final product.

Benefits of Injection Moulding Tooling

There are several benefits of using injection moulding tooling for manufacturing plastic parts and products. For one, the injection moulding process is highly automated, which means that it can produce parts in large quantities quickly and consistently. Additionally, injection moulding can produce parts with high precision and accuracy, making it an ideal process for parts that have complex geometries or tight tolerances.

Another benefit of injection moulding tooling is that it can be customized to meet the specific needs of a particular product or application. This means that businesses can design and manufacture injection moulding tooling that is tailored to their requirements, which can result in lower costs, improved quality, and faster lead times.

Injection moulding tooling is also cost-effective. Because the process is highly automated, it requires minimal labor and can be done using relatively low-cost materials. Additionally, injection moulding tooling is designed to be reusable, which means that businesses can produce multiple batches of parts using the same mould, resulting in lower upfront costs and faster time to market.

Improving Business Performance through Injection Moulding Tooling

The use of injection moulding tooling can have a significant impact on a business's performance by reducing costs, increasing productivity, and improving quality. By customizing the injection moulding tooling to meet their specific needs, businesses can minimize material waste, optimize cycle times, and produce high-quality parts consistently, resulting in significant cost savings.

Additionally, by using injection moulding technology to produce parts, businesses can increase their productivity by reducing the amount of labor required to manufacture products. This enables businesses to produce parts in larger quantities more efficiently and with fewer errors, resulting in faster lead times and increased output.

Finally, improving the quality of the final product through injection moulding tooling can help businesses to improve their bottom line by reducing the number of defective parts and minimizing the need for rework. By creating a consistent and reliable manufacturing process, businesses can enhance customer satisfaction, increase their reputation, and ultimately drive revenue growth.

Conclusion

Injection moulding tooling is an essential component of the injection moulding process, as it affects the quality, consistency, and efficiency of the final product. By customizing injection moulding tooling to meet specific requirements, businesses can reduce costs, increase productivity, and improve quality, resulting in improved business performance. And while the initial capital investment in injection moulding tooling may be high, the long-term benefits of using this process make it a cost-effective solution for businesses of all sizes.